1. Introduction

Warehouse safety is a fundamental aspect of maintaining a productive and secure working environment. The inherent risks of handling heavy machinery, managing large inventories, and operating in a dynamic setting necessitate robust safety protocols. This article outlines five crucial tips designed to improve safety in warehouses, focusing on practices that reduce accidents and enhance operational efficiency.

2. Tip #1: Proper Employee Training

Proper training is the cornerstone of warehouse safety. It equips employees with the essential knowledge and skills needed to perform their duties safely and effectively. Training should cover all aspects of warehouse operations, including the handling of hazardous materials, the operation of machinery, and emergency response procedures. Comprehensive training helps to prevent accidents by ensuring that employees understand and can execute safety protocols correctly.

Regular training sessions are crucial to keeping staff members up-to-date with the latest safety practices and technological advancements. As industry standards and technologies evolve, ongoing education ensures that employees remain informed about new safety protocols, equipment, and regulations. This continuous learning approach helps to minimize risks, reduce the likelihood of accidents, and foster a safer working environment. By prioritizing training, warehouses can enhance their safety culture and ensure that all employees are prepared to handle various scenarios effectively.

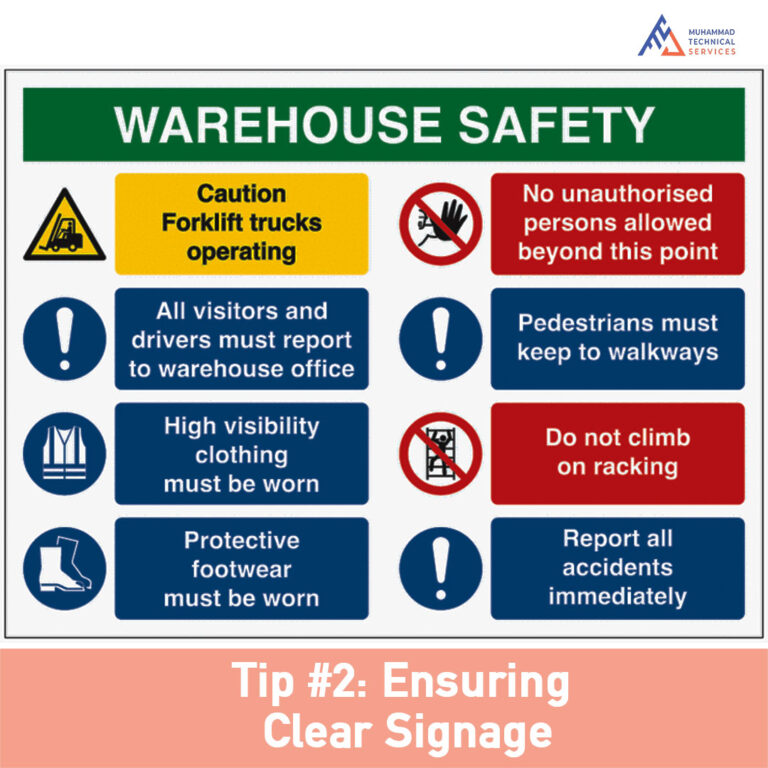

3. Tip #2: Ensuring Clear Signage

Clear signage is vital in guiding workers and fostering a culture of safety within the warehouse. Effective signage helps to identify potential hazards, direct employees through high-risk areas, and provide information on emergency procedures. In a busy warehouse with constant machinery operation, proper signage acts as an early warning system, allowing employees to make informed decisions and avoid high-risk zones.

Signs should be strategically placed in areas with potential hazards, such as near forklifts, loading docks, and storage areas. Additionally, signage indicating emergency exits, first aid stations, and fire extinguishers must be prominent and well-maintained. This ensures that in an emergency, workers can quickly locate essential safety equipment. Regular audits of signage are necessary to ensure that it remains relevant, visible, and compliant with safety standards. Investing in quality signage and maintaining its visibility is a fundamental aspect of a proactive safety approach, reducing downtime caused by accidents and enhancing overall workplace safety.

4. Tip #3: Correct Use of Equipment

The correct use of equipment is critical to preventing accidents and ensuring a safe warehouse environment. Machinery such as forklifts, pallet jacks, and conveyor systems should only be operated by trained and certified personnel. This practice helps to avoid misuse and potential hazards, contributing to a more efficient and safe workflow.

In addition to proper operation, the condition of warehouse equipment, including shelving, plays a significant role in safety. Over time, shelving units can develop signs of wear and tear, which may compromise their ability to support heavy loads. Regular inspections are necessary to assess the integrity of shelving and other equipment. Any signs of rust, bending, or instability should be addressed immediately to prevent potential collapses or accidents. Ensuring that equipment is used correctly and maintained in good condition is essential for minimizing risks and maintaining a safe working environment.

5. Tip #4: Regular Maintenance of Equipment

Regular maintenance is essential for the longevity and safe operation of warehouse equipment. Scheduled inspections and preventative maintenance routines help to identify and address potential problems before they lead to equipment failure or accidents. This proactive approach minimizes the risk of unexpected downtime and costly repairs while promoting a safer workplace for employees.

Machinery such as forklifts, pallet jacks, and conveyor systems should be regularly checked for signs of wear and tear. Lubricating moving parts, replacing worn components, and conducting routine safety checks are crucial practices to prevent equipment malfunctions that could lead to injuries. Additionally, shelving and storage systems must be inspected regularly for structural integrity. Any damage, such as rust or instability, should be promptly repaired or replaced to maintain safety. Prioritizing regular maintenance not only reduces the likelihood of accidents but also demonstrates a commitment to employee well-being and enhances overall warehouse productivity.

6. Tip #5: Promoting a Clean and Organized Workspace

Maintaining a clean and organized warehouse is fundamental to ensuring a safe working environment. Unaddressed spills, clutter, and misplaced items can create dangerous obstacles that increase the risk of accidents. By implementing strict cleanliness protocols, companies can mitigate these hazards and ensure that workers can navigate the warehouse safely.

Effective housekeeping practices, such as promptly cleaning up spills, ensuring clear aisles, and keeping tools and materials in designated areas, contribute to a safer and more organized workspace. Regular inspections should be conducted to identify potential hazards like loose debris, which can lead to slips, trips, or falls. Providing employees with easy access to cleaning supplies and emphasizing the importance of tidiness can foster a culture of responsibility and safety. An organized warehouse not only enhances operational efficiency but also reduces the likelihood of accidents, making it a key component of a successful safety strategy.

7. Expert Insights: Safety Challenges in Modern Warehouses

The safety challenges in modern warehouses have evolved as the industry has advanced. While technological innovations have improved efficiency and productivity, they have also introduced new safety concerns that require careful management. One significant challenge is the integration of automation systems with human workers. As warehouses increasingly adopt robotics, automated guided vehicles (AGVs), and advanced conveyor systems, ensuring the safety of employees working alongside these technologies becomes crucial.

Experts highlight the need for ongoing adaptation of safety protocols to address these emerging challenges. This includes updating training programs to cover new equipment, revising safety guidelines to manage the risks associated with automation, and conducting regular audits to assess the effectiveness of current safety measures. Collaboration between human workers and machines requires clear communication, proper planning, and meticulous monitoring to prevent accidents. Additionally, with the rise of technology, issues such as cybersecurity risks and potential technical malfunctions must be considered. A proactive approach, involving continuous assessment and adjustment of safety strategies, is essential for addressing the evolving safety landscape in modern warehouses.

8. Future Outlook: Technology and Warehouse Safety

The future of warehouse safety is increasingly tied to technological advancements. Automation, artificial intelligence (AI), and smart sensors are expected to play a significant role in reducing workplace accidents by enhancing both hazard detection and safety protocol enforcement. These technologies are transforming how safety is managed in warehouses, offering more proactive and precise approaches to protecting workers.

Automation can minimize human involvement in high-risk tasks, thereby reducing the potential for accidents. Robots and automated systems can handle repetitive, dangerous, or physically demanding jobs, allowing human workers to focus on safer, more complex tasks. AI-driven software can analyze large datasets to predict potential safety risks, such as equipment failures or human errors, before they occur. Smart sensors embedded in equipment and throughout the warehouse can monitor conditions in real-time, detecting issues like overheating machinery, blocked emergency exits, or spills. These sensors can alert supervisors or automatically shut down operations to prevent accidents. By streamlining safety procedures and ensuring consistent adherence to safety standards, these technologies will contribute to safer and more efficient warehouse operations.

9. Final Thoughts

Warehouse safety is a dynamic and ongoing responsibility that demands constant attention and effort. Emphasizing proper training ensures that employees are equipped with the knowledge and skills to handle tasks safely. Clear signage helps guide workers and identify potential hazards, while correct equipment use and regular maintenance are critical for preventing accidents. Maintaining a clean and organized workspace further contributes to a safer environment by reducing risks of slips, trips, and falls.

Prioritizing these safety practices not only protects employees but also enhances productivity and efficiency. A safe workplace minimizes disruptions, reduces downtime, and fosters a positive work culture, ultimately benefiting both the business and its workforce. By continuously adapting to evolving safety challenges and leveraging technological advancements, warehouses can create a safer and more effective working environment.

For comprehensive warehouse maintenance solutions, visit MTS Racks. Our systems are designed to support your safety and efficiency goals, ensuring a reliable and secure warehouse operation.