Pallet flow racking is a dynamic and reliable heavy duty storage solution commonly used in warehouses. It provides an efficient method for storing pallets in an organized manner, designed specifically for First In, First Out (FIFO) product rotation.

At MTS RACKS, we specialize in providing pallet flow racking systems across the UAE, including Dubai, Sharjah, Abu Dhabi, and other cities. These systems are ideal for high-density storage and managing products requiring frequent rotation, such as perishable goods or items with expiration dates.

What is Pallet Flow Racking?

Pallet flow racking consists of inclined roller or wheel lanes that allow pallets to move forward as the front pallet is picked. This system is loaded from the back and picked from the front, requiring a forklift aisle at both ends of the bay. Unlike pushback racking, which only needs one aisle, pallet flow racking provides continuous stock rotation, making it suitable for warehouses that prioritize FIFO operations.

These heavy-duty racks can store between 2 and 20 pallets in a single lane, enabling extremely high-density storage while maintaining accessibility and efficiency.

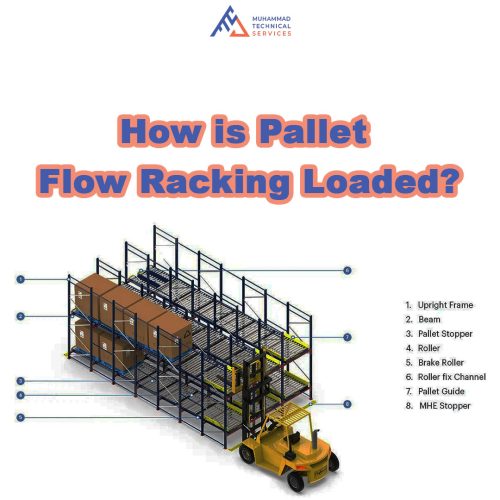

How is Pallet Flow Racking Loaded?

The process of loading pallet flow racking is straightforward:

1. Loading from the Back:

o Pallets are placed on the flow lanes from the high side of the rack.

o Gravity assists in moving the pallets along the slightly inclined roller or wheel lanes.

2. Movement Control:

o Speed controllers or brakes ensure the pallets move safely to the front of the rack.

o Pallet stops at the front end secure the pallets in place for easy and safe forklift access.

3. Picking from the Front:

o When a pallet is picked from the front, the next pallet automatically moves forward into position.

Benefits of Pallet Flow Racking:

Pallet flow racking offers several advantages, making it an excellent choice for high-demand and high-density storage facilities:

1. Efficient Use of Space:

o Maximizes vertical and horizontal storage capacity.

o Accommodates multiple SKUs, enabling easy access in one working aisle.

2. Faster Picking and Restocking:

o Pallets automatically slide forward, reducing the time and effort required for loading and unloading.

o This improves workflow efficiency and reduces worker fatigue.

3. Enhanced Safety:

o The automated sliding mechanism minimizes the physical effort needed for manual operations, lowering the risk of worker injuries and accidents.

4. Ideal for FIFO Rotation:

o Perfect for managing inventory with strict rotation requirements, such as food, pharmaceuticals, or time-sensitive products.

Main Components of Pallet Flow Racking

1. Rack Structure:

o Built from structural or roll-formed steel uprights, ensuring durability and strength.

2. Flow Lanes:

These lanes determine how pallets move within the system:

o Steel Skate Wheel Rollers: Cost-effective and ideal for standard wood pallets, offering a weight capacity of up to 2,000 lbs.

o Magnum Wheel Rollers: Made from reinforced resin for durability, with a capacity of over 3,000 lbs. Ideal for freezer or cold storage environments.

o Full-Width Rollers: Highly versatile and heavy-duty, suitable for various pallet sizes and types, including steel containers and plastic totes.

Applications of Pallet Flow Racking

Pallet flow racking is commonly used in industries where FIFO inventory management is crucial:

• Food and Beverage: Ensures perishable goods are rotated efficiently.

• Pharmaceuticals: Maintains proper stock rotation for time-sensitive products.

• Retail and Distribution: Optimizes warehouse space for large volumes of inventory.

• Cold Storage: Reduces energy costs by maximizing space efficiency in temperature-controlled environments.

Why Choose MTS RACKS?

At MTS RACKS, we provide high-quality pallet flow racking systems tailored to meet your warehouse storage needs in the UAE. Whether you’re based in Dubai, Sharjah, Abu Dhabi, or other cities, our team can help design, install, and optimize your racking system for maximum efficiency and durability.

Contact MTS RACKS

Ready to upgrade your warehouse with pallet flow racking? Contact MTS RACKS today, and let our experts help you find the best industrial pallet racking system for your space. With efficient storage solutions, you can streamline operations, reduce costs, and achieve your business goals.