When planning your warehouse operations, you may consider expanding your facility or increasing your inventory to meet growing demand. However, if space is limited, upgrading your storage system can present challenges.

At MTS RACKS, we understand the importance of efficient storage solutions. Our pushback racking systems, available across the UAE, including Dubai, Sharjah, Abu Dhabi, and beyond, offer high-density inventory storage. These durable systems are ideal for warehouses looking to optimize space while accommodating changes in inventory or future expansion.

What is Pushback Racking?

Pushback racking is a heavy-duty shelving system designed for high-density storage. It allows pallets to be stored 2 to 6 deep, providing exceptional storage capacity. One of the best features of these racks from MTS RACKS is their low maintenance requirements and robust construction, making them a long-term investment for any facility.

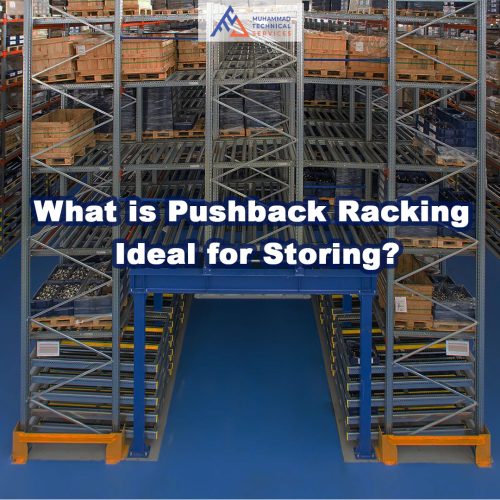

What is Pushback Racking Ideal for Storing?

Pushback racking is perfect for facilities needing high-density storage with limited space. Each level of the rack can store different SKUs, simplifying stock organization and rotation.

This type of racking is built for Last In, First Out (LIFO) inventory rotation, which means it may not be suitable for perishable goods. For perishable inventory, we recommend pallet flow racking, as it uses a First In, First Out (FIFO) system for better stock rotation.

How Does Pushback Racking Work?

Pushback racking uses gravity to streamline the loading and unloading process. Here’s how it works:

1. Loading:

o Pallets are placed on nested carts or carriages using a forklift.

o The first pallet is loaded onto the cart at the front of the bay.

o As additional pallets are loaded, each one pushes the previous pallet deeper into the rack. The last pallet rests directly on the rails.

2. Unloading:

o The process is reversed. When the first pallet is removed, the next pallet automatically moves to the front of the bay due to the slight incline of the rails.

This gravity-assisted system makes loading and unloading quicker and safer.

What Makes Pushback Racking Different?

Pushback racking stands out because it:

• Stores 2-6 pallets deep in the same bay, offering up to 90% more storage density compared to standard selective racking.

• Requires no aisle behind the racks, making it ideal for facilities where space is tight, such as those placing racks against walls.

• Reduces the risk of damage since forklifts only operate at the front of the racks, unlike drive-in racking that requires forklifts to maneuver inside the structure.

• Speeds up the loading and unloading process, improving warehouse efficiency.

Main Components of Pushback Racking

1. Rack: The structure includes heavy-duty, adjustable frames made of structural or roll-formed steel.

2. Rails: Inclined, durable rails guide the pallets and facilitate smooth movement.

3. Carts: Nested carts rest on the rails and can hold various pallet sizes. They can support weights up to 1,360 kg, with options for customization for heavier loads.

Why Choose MTS RACKS for Pushback Racking?

At MTS RACKS, we specialize in offering efficient and durable shelving solutions across the UAE, including Dubai, Sharjah, Abu Dhabi, and more. Our expert team can help you design the ideal storage system tailored to your specific needs.

Pushback racking is an excellent choice for facilities requiring high-density storage and efficient inventory management. To learn more about our industrial shelving systems and find the perfect solution for your warehouse, contact MTS RACKS today.

Transform your storage space with MTS RACKS your trusted partner for advanced racking solutions in the UAE.